Swedish researchers have revolutionized 3D printing by developing micro-optics made of quartz glass on fiber optics. They promise faster internet, improved sensors and advanced imaging systems while avoiding damage to the fiber optic coatings caused by high temperatures. Image credit: David Callahan

Swedish researchers have 3D printed fused silica micro-optics onto fiber optics, improving internet speeds and connectivity. This more robust and precise technology could revolutionize remote sensing, pharmaceuticals and photonics.

For the first time in communications, Swedish researchers have managed to 3D print fused silica micro-optics directly onto the tips of optical fibers, areas as small as the cross-section of a human hair. This breakthrough could lead to faster internet speeds and improved connectivity, as well as the development of smaller sensors and more compact imaging systems.

Reporting in the journal ACS NanoAccording to researchers at the KTH Royal Institute of Technology in Stockholm, integrating fused silica optical devices with optical fibers enables numerous innovations, including more sensitive remote sensors for the environment and healthcare.

The printing techniques they reported could also prove valuable in the production of pharmaceuticals and chemicals.

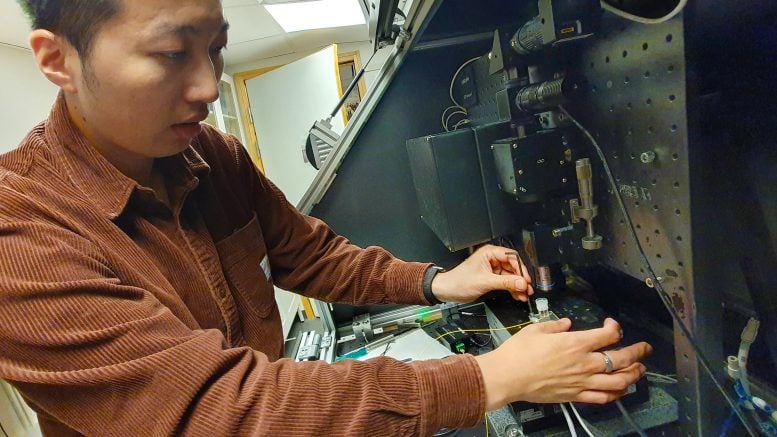

Lee-Lun Lai demonstrates the setup for printing quartz glass microstructures onto a fiber optic. Photo credit: Lee-Lun Lai demonstrates the setup for printing fused silica microstructures onto a fiber optic.

Advances in printing technology

KTH Professor Kristinn Gylfason says the method overcomes long-standing limitations in patterning optical fibre tips with fused silica, which he says often require high-temperature treatments that compromise the integrity of temperature-sensitive fibre coatings. Unlike other methods, the process starts with a base material that does not contain carbon. This means that high temperatures are not required to drive out carbon and make the glass structure transparent.

The study’s lead author, Lee-Lun Lai, says the researchers printed a quartz glass sensor that, after several measurements, proved to be more resilient than a standard plastic-based sensor.

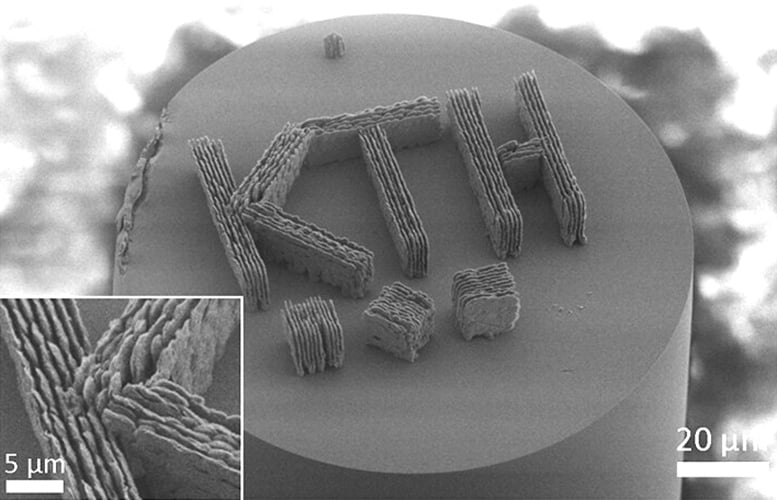

Microscopic image of a printed glass demonstration structure at the tip of an optical fiber. Photo credit: David Callahan

“We demonstrated a glass refractive index sensor integrated into the fiber tip, which allowed us to measure the concentration of organic solvents. This measurement is challenging for polymer-based sensors due to the corrosiveness of the solvents,” says Lai.

“These structures are so small that you could fit 1,000 of them on the surface of a grain of sand, which is about the size of the sensors used today,” says study co-author Po-Han Huang.

The researchers also demonstrated a technique for printing nanogrids, ultra-small patterns etched onto surfaces at the nanometer scale. These are used to manipulate light in precise ways and have potential applications in quantum communications.

According to Gylfason, the ability to 3D print arbitrary glass structures directly on the fiber tip opens up new frontiers in photonics. “By bridging the gap between 3D printing and photonics, the implications of this research are far-reaching, with potential applications in microfluidic devices, MEMS accelerometers and fiber-integrated quantum emitters,” he says.

Reference: “3D Printing of Glass Micro-Optics with Subwavelength Features on Optical Fiber Tips” by Lee-Lun Lai, Po-Han Huang, Göran Stemme, Frank Niklaus and Kristinn B. Gylfason, March 29, 2024, ACS Nano.

DOI: 10.1021/acsnano.3c11030

The study was funded by the Sweden Taiwan Research Projects 2019 and the Swedish Foundation for Strategic Research.